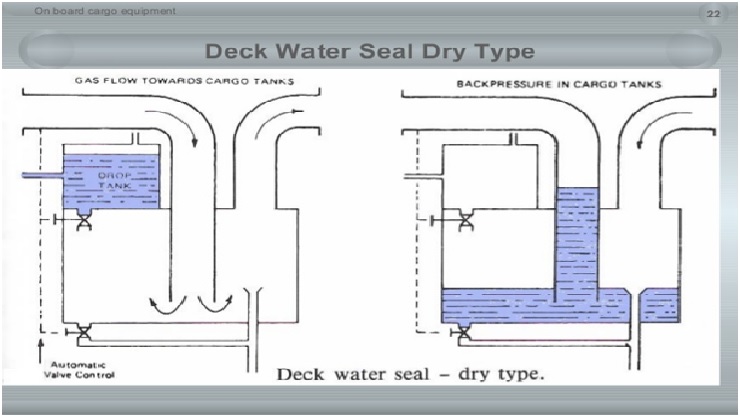

The dry type deck water seal has an upper reservoir (drop tank) and a lower reservoir (sealing tank). The flow of water from the drop tank to the sealing tank and from the sealing tank to the overboard discharge is controlled automatically via level sensors and other control equipment.-

The above figure indicates a typical dry type deck water seal with upper and lower reservoirs. The upper reservoir is filled with water at all times and supplies water to the lower reservoir.

The lower reservoir is empty during system operation (gas flowing to tanks) and filled with water when the inert gas blower is shut down, either because of normal stopping or because of automatic system shutdown activated by off-design conditions. The filling and drainage of the upper and lower reservoirs is triggered automatically by the sensing of levels in the sealing tank and drop tanks, by the on/off status of the blowers or by the gas-to-tank push button switch.

The upper and lower reservoirs are usually equipped with float-type level sensors.

The IMO Guidelines indicate that the deck seal lower reservoir will be filled with water when the cargo tank pressure exceeds the blower discharge pressure. However, there appears to have been little action by administrations to ensure that this detail of the Guidelines is followed by, for example, requiring devices to sense the pressure differential between the inert gas main and the pressure at the blower discharge.

The following monitoring equipment options should be considered as having the potential to enhance the safety of operation of the deck seal: