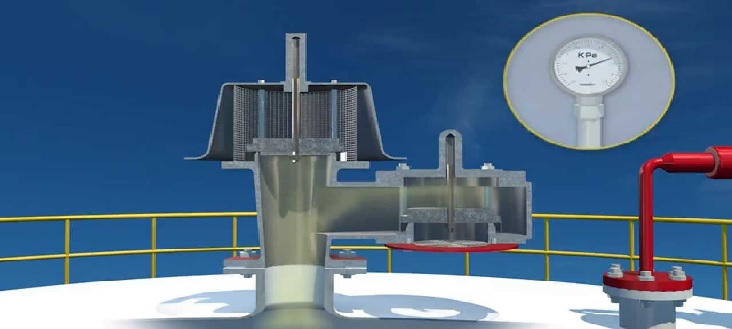

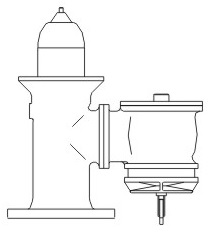

Pressure vacuum valve or PV valve in the ventilation system will prevent either over or under pressure. They are set usually so that tank pressure of about 0.14 bar will lift the main valve (The smaller valve will lift along with it) and release excess pressure. The vapour passes to atmosphere through a gauze flame trap. Drop in tank pressure compared with that of the outside atmosphere will make the small valve open downwards to equalize internal pressure with that outside

Pressure vacuum valve or PV valve can relieve moderate changes in tank pressure due to variations in temperature and vapour quantity. A drop towards vacuum conditions as the result of the condensation of steam will also be handled by the valve. Rapid pressure rise due to an explosion would not be relieved.

In other words pressure vacuum valve can be explained as:

Pressure vacuum valve or PV valve can relieve moderate changes in tank pressure due to variations in temperature and vapour quantity. A drop towards vacuum conditions as the result of the condensation of steam will also be handled by the valve. Rapid pressure rise due to an explosion would not be relieved.

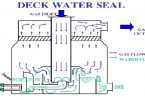

The fast rate at which a tank is filled while loading produces a very rapid expulsion of the previous contents (vapour and inert gas). The pressure vacuum valve is not designed as a filling vent and neither should the tank hatch be left open. The latter method of venting can cause an accumulation of flammable vapours at deck level. Tanks should be vented while filling, through mast head vents or through special high velocity vent.

The high velocity pressure / vacuum valve is a device to prevent the passage of flame consisting of a mechanical valve which adjusts the opening available for flow in accordance with the pressure at the inlet of the valve in such that the efflux velocity cannot be less than 30 m/s (98 ft. /sec) under all flow rates and the actual condition of installation.

how to set the alarm settings of pressure vaccum valve, how it works?

test the PV valves at what value must be pressurised the cargo tank?