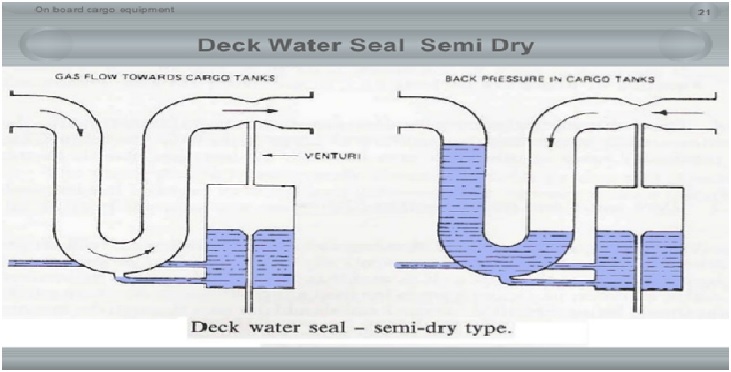

The semi-dry deck water seal has a separate holding chamber which is connected by pipe to the inert gas main via an eductor. Instead of passing through a water trap, the inert gas flowing through the venturi creates a suction effect in the holding tank which draws the sealing water from the loop seal into the holding tank. This mitigates the undesirable ‘carry over’ of moisture to the cargo tanks.

When the gas flow ceases, the venturi effect is lost and the water from the holding tank rapidly flows back into the inert gas main loop seal thus creating a water seal which serves to prevent the backflow of hydrocarbon vapour and/or inert gas from the hazardous to non-hazardous area.

The following monitoring equipment options should be considered as having the potential to enhance the safety of operation of the deck seal: