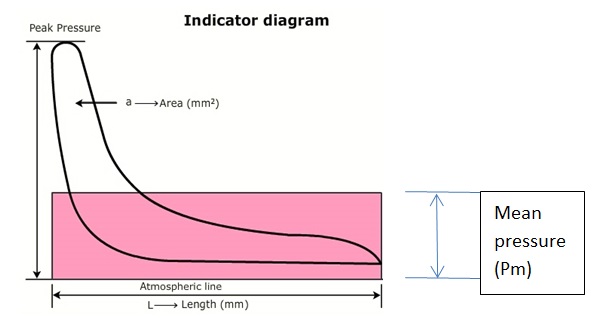

Power card or PV diagram can be used to measure indicated power in diesel engines. The area within the diagram represents the work done within the cylinder in one cycle.

FIG.: Power card

The area can be measured by an instrument known as ‘Planimeter’ or by the use of the mid ordinates rule. The area is then divided by the length of the diagram in order to obtain mean height. This mean height, when multiplied by the spring scale of the indicator mechanism, gives the indicated mean effective pressures for the cylinder. The mean effective or average pressure [Pm] can now be used to determine the work done in the cylinder. Following calculations can be made to the area of indicator diagram to measure indicated power.

Interesting. Thank you!

Hi, how to calculate the mean pressure?

Thanks