- Initial ship and ship / shore or ship / ship safety checklist shall be made by chief officer which shall also be checked by the concerned duty officer and signed by both. The correct status of the safety checklist should be maintained by the duty officer throughout the cargo operations. Releiving duty officer shall, prior taking over the watch, make a proper round of the deck and pumproom with special regard to the safety checklist and shall note down the deficiencies. He shall then bring to the notice of the previous duty officer all the deficiencies noted and have them corrected immediately. Any deficiency requiring chief officer’s or master’s attention should be immediately conveyed.

- Chief officer is incharge of all cargo operations and shall ensure that duty officers follow these standing orders and also instructions given by him.

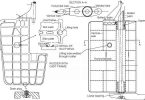

- Chief officer shall carry out the initial line setting and this shall be verified by the duty officer. Opening / closing of the sea chest valves and overboard valves shall only be carried out by chief officer. Correct operation of the sea suction valves and pumps should be carried out when taking dirty ballast to avoid the escape of oil by sea.

- Cow operations shall be carried out by chief officer. Cow checklist shall be completed prior carrying out operation.

- Method of communication should be agreed with terminal and endorsed on ship / shore or ship to ship safety check list and or ship / shore (ship to ship) loading / discharging agreement plan. Proper functioning of the ship / shore communication should be checked prior to and throughout all cargo operations. Communication system should be checked at regular intervals and logged in the ccr log. The duty officer should continously man the ship / shore communication sytem.

- Important orders:

- when loading / discharging cargo alongside berth, moorings shall be attended to at regular intervals to ensure that the vessel is alongside the berth at all times and does not surge in the fore & aft direction. Mooring party shall at all times have walkie-talkie for communication with ccr and shall be instructed about correct handling of the moorings, mooring equipment and power units. Mooring party should be instructed to take regular rounds on deck for moorings and gangway.the rate of loading, discharging, ballasting and de-ballasting, including tidal variations shall be taken into account for correct and timely handling of moorings. As far as possible not more than two mooring wires or ropes should be handled at any one given time. Mooring hawsers which are not permanently on the drum should be secured on the bitts with a figure of eight.

- when handling cargo at s.p.ms., mooring station on the fo’c’le shall be manned by one deck duty hand with means of communication with the ccr.

- when handling cargo during lightering operations with a daughter vessel, mooring party should be instructed to also watch the fenders between the vessels and own vessel’s anchor in addition to mooring wires and ropes.

- When handling cargo at a berth using loading arms, extra care and precaution should be taken to ensure that the vessel does not move at the berth and remains upright at all times.

- Ensure that all doors and vents to the store rooms fwd and aft, accomodation and to all other compartments are shut prior to and during the cargo operations.

- Ship’s manifold should be continuously manned by one deck duty hand with means of communication with the ccr. He should be properly instructed of his duties during the manifold watch.

- Cadet or pumpman shall have one walkie-talkie with instructions of duties to be carried out.

- Any leakage of oil on deck or in pumproom should be immediately reported, arrested and cleaned on war footing.

- Deck hands on watch should be instructed to keep a good look-out for signs of oil in the ship’s vicinity and smoke from the funnel. Any trace of oil in the water in the ship’s vicinity should be immediately reported to the chief officer and master. Engine room should be notified in case the uptakes are found to be smoking. If the smoke persists then the master should be informed.

- Oil spill control and clean-up equipment should be kept in readiness at their designated locations.

- Drip tray plugs and air pipe overflow tray should be in place at all times and drip tray drain valves should not be opened without the express authorisation of the duty-officer. When draining the drip trays, the tanks into which the drains are leading should be de-pressurised.

- Inert gas branch line valve leading to the individual tanks should be kept open at all times and should not be closed without the express permission of chief officer. Every event of closing and opening of these branch i.g. valves should be recorded in the ccr log alongwith the reason of closure. The valves should be re-opened upon completion of work.

- Cargo tanks should be inerted upto below 8 % oxygen and maintained at sufficient positive pressure at all times prior to, during and after cargo operations. I.g. pressure in the tanks should be recorded in the log book.

- Oxygen content of the deck inert gas line should be checked with portable o2 meter to verify the accuracy of the oxygen analyzer and recorder. Inert gas log shall be filled up at regular intervals. As far as possible i.g. oxygen content should be maintained around 5%.

- Only one door should be used on upper deck for exit and entry from accomodation and ship staff should be instructed accordingly.

- Duty officer should ensure that :

- Vessel flys courtesy flag, company’s flag and ensign when alongside a berth or at s.p.m. at appropriate times. Certain countries require their flag to be flown during day and night as well.

- Displays ‘b’ flag during daytime and flashing red light during night

- Ship / shore and ship / ship agreement plan shall indicate, in writing, notices required for reduction and stopping of cargo. Loading rates requested by own vessel as well as by the daughter vessel shall be stated in writing in the plan.

- Pumpman and cadet should be instructed to frequently watch the hydraulic oil tank level for cargo valve handling system and replenish same only upto maximum mark and report every filling to the duty officer. The duty officer should enter in the ccr log the time and quantity of oil replenished. Sudden and excessive loss of oil from the system should be immediately investigated by taking rounds on deck and in pumproom to look for signs of leak. The pressure gauge in the ccr should be frequently watched to see if pressure is being lost and pumps are cutting in / out frequently. In such cases the deck and pumproom area should be checked for oil leaks. The chief officer should be informed if any abnormal loss of oil is noticed.

- Duty officer should ensure that all walkie-talkies are used with covers and microphones are slung on shoulder / waist and are used properly by everyone. Communication should be tested with all parties on deck at regular intervals

- All important parameters of loading, discharging, ballasting, starting and completion of tanks and all other major events should be logged in the ccr log. Hourly levels of tanks should be noted and rates should be calculated in the ccr loading / discharging log.

- Conversation with shore personnel should only be to the extent required and if in any doubt about the information asked for by the shore personnel, master should be called for handling the same.

- During cargo operations entry in the ccr should be restricted for official business only.

- Chief officer will make loading / discharging plan which shall be followed by the duty officers. When in doubt or in case the plan cannot be followed, the same should be brought to his notice immediately.

- Cargo control room and communication systems of shore / ship shall be manned at all times during cargo operations.

- Mooring party should be instructed to look for oil leaks from fwd and aft hydraulic mooring system on deck and in hydraulic room.

- Deck scuppers should remain plugged prior to and during cargo operations. Opening of scuppers to release collected rain water on deck should be done only when expressly authorised by the duty officer who should first inspect whether the collected water is free from oil. Correct procedure of drainage should be instructed to the crew handling same.

- Anchors when not in use shall be secured and chain lashed with the bow stopper in place.

- Any abnormal operation of cargo and ballast pumps should be immediately brought to the notice of the duty engineer and appropriate corrective action should be taken.

- Pumproom should be kept ventilated during cargo operations and entry / exit of personnel should only be with the express permission of the duty officer.

- Initial and final tank guagings shall be done under direct supervision of the chief officer.

- Topping up of the tanks should be done by the chief officer.

- Connection and disconnection of loading arms / hoses should be done under the supervision of the duty officer.

- All officers should follow the above standing orders in addition to all established safe tanker practices, comply with the local port regulations and owners standing instructions and take prudent action deemed necessary for the safety of the personnel, ship, terminal, property and the environment.

- All officers to read, understand, sign and comply with these standing orders.