We could look at eccentric loading on a crane as the weight or load that is off the vertical axis of the crane. There are lots of different cranes, but let’s dive in, bounce around a bit and speak in general terms. We’ll start by taking a look at what a crane does and consider our options. A crane is designed to lift loads up, which is a simple but necessary start. Cranes generally have a boom extending out from the central axis of the crane.

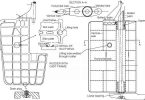

Now focus on this. The mass of the boom will be acted on by gravity and “pulled on” while it’s sticking out. And the straighter it sticks out, the more the effect on the crane. That is, the more the mass of the boom will be acting to try to pull the crane over. And that’s with no load. Let’s do something crude but that might help. Pick up a broom near the end of the handle. Hold your arm straight out and hold the broom straight up in the air. You can feel the mass of the broom. Now lower the broom to where it is sticking straight out from your arm. There is a greater torque on your shoulder now because you’re holding the broom straight out. The tower crane, which is used in the construction of tall buildings, has a movable counterweight. That allows the operator to “balance” the effect of the load and the effect of the counterweight. They’ll offset each other to pretty much eliminate any eccentric loading. Obviously the tower crane can’t handle much of that without being ripped off the structure to which it is attached..On the “back” of a “regular” crane is a counterweight to offset the mass of the boom.

Without the counterweight, the boom may tip the whole machine in the direction the boom is pointing. Recall that when we stick the boom out straighter, it tends to “torque” the crane off its vertical axis more. Why wouldn’t it? The counterweight is doing its job. But there is no perfect match here between the mass in the counterweight and the boom. That’s because as the boom is lowered or raised, the “effective mass” of the boom changes, even with no load on it. Now let’s do a “pick” with the machine. A pick is a lifting operation. When we set up a crane, we generally have what are called outriggers to spot. These are “legs” that extend out from the crane and have a “foot” on them that is hydraulically shoved down on cribbing. These outriggers make the lifting platform more stable, and you can see why. The effective “footprint” of the machine is much greater with the outriggers set. When we hook up a load and lift it, the operator will be trying to keep the boom as “straight up in the air” as possible. This will minimize that “off-center loading” or eccentric loading. He’s got the knowledge, skill and experience to use the machine in a way that will prevent eccentric loading from permitting a safe pick.