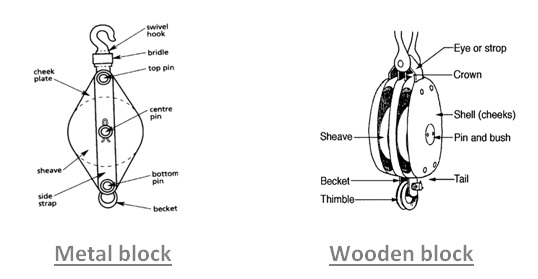

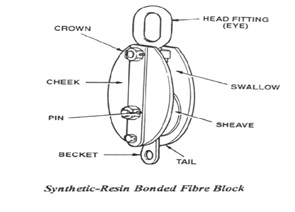

A block is a portable pulley, made of wood, metal, synthetic-resin bonded fibre (SRBF) or combinations of materials.

General Information

Blocks can be fitted with a hook as an alternative to an eye, andthe hook or eye can be fixed or swivel types. They may have more than one sheave; a single block has one sheave, a double block has two and a triple has three.

Wooden B locks are classified by their size, which is the length from crown to tail measured in millimetres round the shell; and it will take a rope one-tenth of its size. (Rope measured by its diameter in millimetres).

Metal Blocks are classified by the size of rope for which they are designed and this is normally marked on a plate affixed to the cheek.

SRBF Blocks are also classified by the size of rope for which they are designed and this is stamped on the binding of the block.

Study the part of blocks as shown in Figures