Here I have referred to a particular MAN B & W MC Engine. You should consult your manual also as surveyor mostly asks about the engine on your ship.

Precautions and procedures before removing liner:

- Inform company and take permission.

- Take immobilisation certificate from port state control.

- Read the manual and have a tool box meeting with everyone involved in the job. Discuss the complete procedure.

- Prepare important tools and spares required for overhauling liner as given in the manual.

- Prepare risk assessment and make sure all personal safety equipment are used

- Close the shut-off valves on the starting air receivers.

- Close all the shut-off valves in the control air supply unit and spring air and open the drain cocks in the two air receivers.

- Close by hand the automatic starting air shut-off valve and open the vent and drain valve to the main starting air piping on the engine as well as the vent valves on the automatic starting air shut-off valve, and leave them in this position until maintenance work is completed.

- Open all indicator cocks on the cylinder covers and leave them in this position until maintenance work is completed.

- Engage turning gear (gear pinion must be in engaged position) and lock the lever

- Stop main lube oil pump and switch off the breaker.

- Once the engine jacket temperature comes down, shut the inlet water valve for the unit to be overhauled.

- Keep other units in Jacket preheating system to maintain the jacket temperature

- Drain the jacket water of the concerned unit from exhaust v/v and liner.

- Remove jacket water connection.

- Shut the fuel oil to the particular unit whose liner is to be removed.

- Dismount the cylinder head using dedicated lifting tools.

- Remove the sealing ring from the top of the cylinder liner.

- Turn the piston down far enough to make it possible to grind away the wear ridges at the top of the liner with a hand grinder.

- Remove the piston together with piston gland.

Liner Removal procedure for MAN engine (MC engines)

- Disconnect at the non-return valve all the pipes leading from the cylinder lubricator to non- return valves.

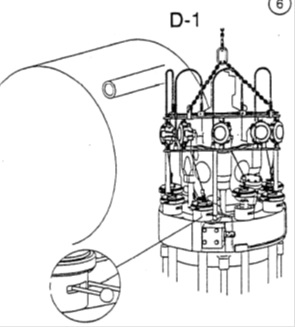

- Check the condition of liner lifting tool and associated parts.

- Ensure the safety strap in the lifting hook is working properly.

- Tighten the two lifting tool screws in the liner as per the rated torque is given in the manual on both sides.

- Attach the crossbar to engine room crane.

- Hook the chain from the lifting cross bar on the lifting screws and lift the cylinder liner with the cooling jacket out of the cylinder frame.

Fig.: Liner removal tool MAN B & W

Note: Never lift the cylinder liner with the crossbar attached to lifting screws in the cooling jacket