There are three basic types of pipeline systems:

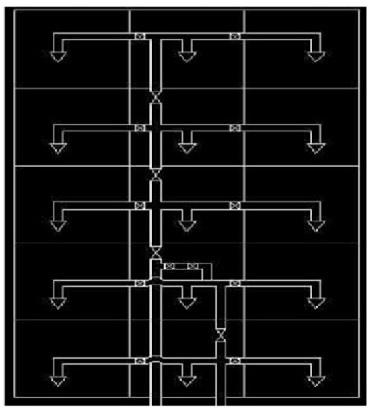

- Direct system

- Ring main system

- Free flow system.

Direct line system

Advantage:

- Quick loading & discharging.

- Short pipe line.

- Less bend.

- Less loss of pressure due to pipe line friction.

- Direct line to provide better suction.

- Time of washing the line is short.

- System is cheaper than the other system.

- Leak is minimized.

- Easy to operate so less training is required.

- It is easy to separate each cargo.

Disadvantage:

- In case of leaking the control of leakage is difficult.

- This system is very inflexible.