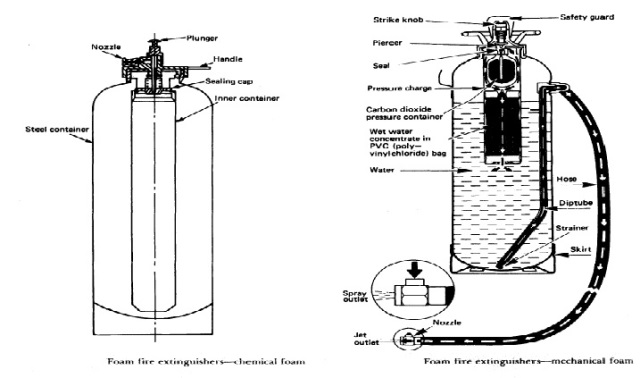

There are two basic types of foam, chemical and mechanical.

-

Chemical Foam

Chemical foam is formed by mixing together a solution of an alkali (usually sodium bicarbonate), an acid (usually aluminum sulfate), water and a stabilizer. The stabilizer is added to make the foam tenacious and long-lived. When these chemicals react, they form a foam or froth of bubbles filled with carbon dioxide gas. The carbon dioxide in the bubbles has little or no extinguishing value.

Its only purpose is to inflate the bubbles. From 7 to 16 volumes of foam are produced for each volume of water.

Premixed foam powders may also be stored in cans and introduced into the water during fire-fighting operations. For this, a device called a foam hopper is used. Or, the two chemicals may be premixed with water to form an aluminum sulfate solution and a sodium bicarbonate solution. The solutions are then stored in separate tanks until the foam is needed. At that time, the solutions are mixed to form the foam. Few chemical foam systems are still in use aboard vessels.