SEMI BUILT

- In this, several parts such as crank-throw and pins are cast out of a single piece.

- Today, crankshafts for large 2 stroke cross head engines are of the semi built type.

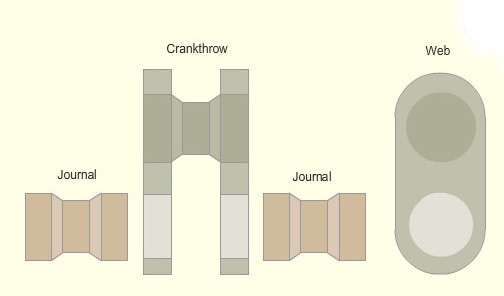

- In this method of construction the crankshaft “throws” consisting of two webs and the crank pin are made from a single forging.

- The webs are bored to take the separately forged and machined main journals which are fitted into the webs using the shrink fitting method.

- The advantages of this method of construction is that by making the two webs and crank pin from a single forging the grain flow in the steel follows the web round into the crank pin and back down the other web.

- The crank pin and webs are a single forging, the webs can be reduced in thickness and a hole is sometimes bored through the crank pin as shown, reducing the weight without compromising strength.

- But the hoop stress developed due to shrink fitting of main journals, can lead to cracks if enough material is not there. Hence there should be a balance.

- After the main journal is fitted in the crank web, witness marks are marked in journal and web. These should be checked during crankcase inspections.

- These types are assembled from separate journal pins and complete crank throws. A crank throw comprises of crank pin and webs. Shrink fits are used for assembly. These types are also found in some of the larger medium speed engines. The crank throw is manufactured by continuous grain forging method.

FIG.: SEMI BUILT CRANKSHAFT

I have found a kinde of moveable cranks that makes the shaft to move, easier and less power to be biose now i need your help to approtch my idea