What Causes the “Cappuccino Effect”?

There are several ways in which air may be introduced into fuel oil:

- The bunker barge may inject compressed air into its tanks prior to joint soundings being taken to increase the apparent volume of the fuel oil before it is transferred.

- Compressed air may be injected into the fuel oil during the transfer, either in the vicinity of the discharge pump or into the tank or into the discharge line. This may be by using the compressed air equipment designed to blow through the pipelines after discharge, or via a separate system. The stripping of bunker tanks using a positive displacement pump means that air will be drawn into the fuel oil when pumped. Consequently, excessive stripping by the bunker barge may also result in the “cappuccino effect”.

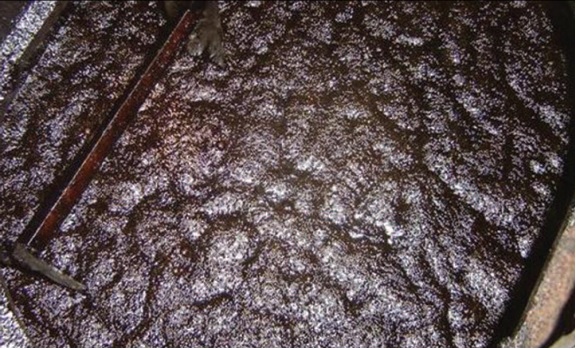

Fuel oil in a double bottom tank displaying frothing and foaming consistent with the cappuccino effect

I never learn this in maritime school. Thanks MG for uptodate articles on latest ideas and knowledge. While taking ullage, i’ll refer this to my pumpi..