Tie rods

Tie rods are bolts which keep the whole engine structure(cylinder block, column, bedplate) under compression.

Tie rod function:

- Keep whole engine under compression

- Provide for fatigue strength

- Provide for proper running gear alignment which prevents fretting

- Helps to reduce the bending stress being transmitted to the transverse girder

- Transmits the gas forces which act on the cylinder head.

- The firing pressure force of the piston is directly transmitted to the main bearing and consequently to the engine frame through the tie rod support.

How tie rods are prevented from vibrating?

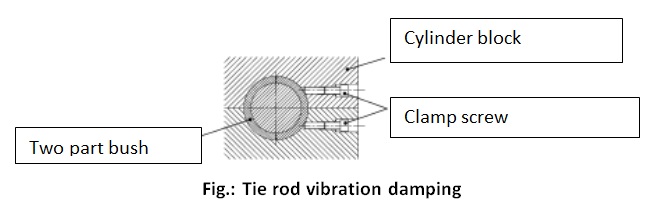

Each tie rod is equipped with a two-part bush which is firmly fastened by the two clamp screws, located at the bottom of the cylinder block. These guide bushes prevent the tie rod from vibrating. For additional vibration damping the space around the lower part of the tie rod till mid-column is filled with oil which enters through a filling bore in way of the crosshead guide plate.

Pinching screws are provided to prevent tie rods from vibrating.

When we r going to check the tie bolts tightness that time what we have to do? Is it important to loose the clamping screw? Can u provide some better photo of the bush and pinching screw.