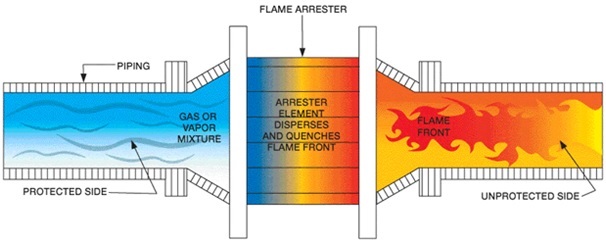

In other words flame arrester can be explained as :

A Flame Arrestor is a device which allows gas to pass through it but stops a flame in order to prevent a larger fire or explosion.

Construction of flame arrester

Typically a flame arrester comprises a housing, an element and connection(s) to secure it to pipe work or equipment. The element is the device that quenches the flame and the majority of constructions used incorporate a form of “filter” that provides small apertures through which the process gas will flow but will prevent flame transmission. The flame front is broken down in the “filter” into smaller flamelets which are cooled by the large heat capacity of the element thus extinguishing the flame. Materials used for the “filter” element include crimped metal ribbons, woven wire gauze, sintered materials and honey comb materials. Because of its construction, the element will cause a pressure drop or an obstruction to process flow. In order to mitigate this increased resistance to flow, the element area is usually larger than the cross sectional area of the pipe work. Larger elements also have a greater heat capacity.

Other types of flame arrester include devices which incorporate a small aperture that ensures the velocity of the gas being emitted exceeds the burning velocity of that gas and thus will not transmit the flame. Alternatively, the gas may be bubbled through a liquid or water in a manner that provides a liquid barrier to flame transmission.

Flame screens should be: