The basic principle of electric arc welding is that a wire or electrode is connected to a source of electrical supply with a return lead to the plates to be welded. If the electrode is brought into contact with the plates an electric current flows in the circuit. By removing the electrode a short distance from the plate, so that the electric current is able to jump the gap, a high temperature electrical arc is created. This will melt the plate edges and the end of the electrode if this is of the consumable type.

Electrical power sources vary, DC generators or rectifiers with variable or constant voltage characteristics being available as well as AC transformers with variable voltage characteristics for single or multiple operation. The latter are most commonly used in shipbuilding.

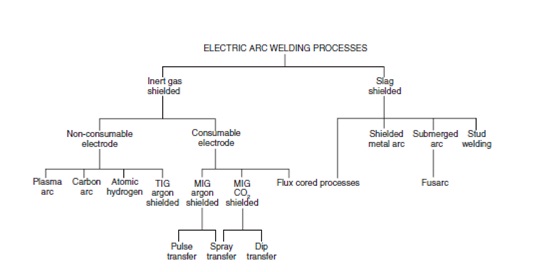

The range of manual, semi-automatic, and automatic electric arc welding processes which might be employed in shipbuilding.

Leave a Comment