In order to reduce or eliminate the adverse heeling effect of grain shift, the following methods may he used:

- a) Shifting Board (F+P)

- b) Over stowing (F+P)

- c) Strapping and Lashing (F+P)

- d) Bundling (F)

- e) Saucering (F)

- f) Feeders (F)

here – (F-filled,P-partly filled)

Shifting Board

- Longitudinal divisions (called shifting board), which must be grain tight may be fitted in both “filled” and “partly filled compartments”.

- In “filled compartments, they must extend downwards from the underside of the deck or hatchcovers, to a distance below the deckline of at least one-eighth the breadth of the compartment, or at least 0.6m below the surface of the grain after it has been assumed to shift through an angle of 15o

- In a “partly filled compartment’, the division, should extend both above and below the level of grain, to a distance of one-eighth the breadth of the compartment.

Over stowing

- For a partly filled compartments –topped off by loading bagged grain or other suitable cargo

- Surface to level off over and spread with separation cloth (gunny sack) or wooden boards

- Overstowed with sound well filled bags to a height of 1/16th the maximum breadth of the free grain surface, or to a height of 1.2 m whichever is greater

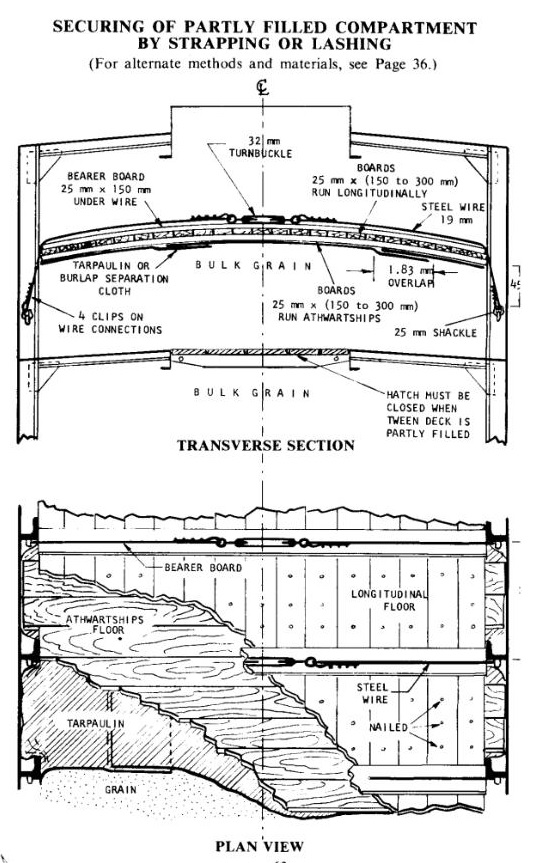

Strapping or lashing

Leave a Comment