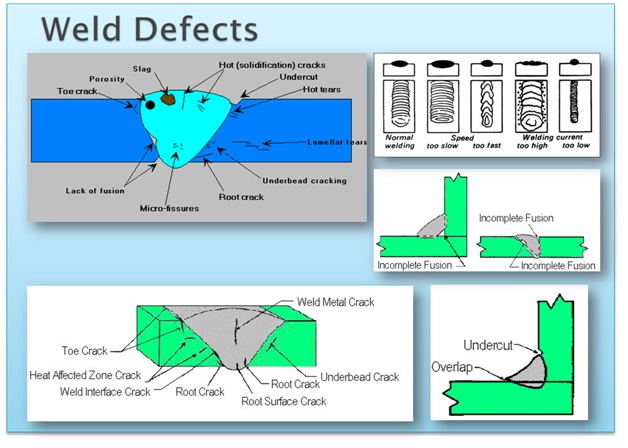

The defects in the weld can be defined as irregularities in the weld metal produced due to incorrect welding parameters or wrong welding procedures or wrong combination of filler metal and parent metal.

It can simply be defined as:

“Defects introduced during welding beyond the acceptance limit that can cause a weld to fail”.

A defect does not allow the finished joint to withstand the required strength (load).

Visual defect /Surface weld defect/External defect

- –Over laps

- –Under cuts

- –Excessive penetration

- –Surface porosity

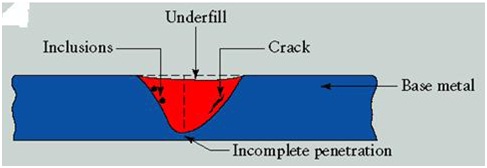

Hidden defect/sub surface weld defect/Internal defect

- –Lack of fusion

- –Lack of penetration

- –Shrinkage cavity

- –Slag inclusion

You may also know Details of welding defects

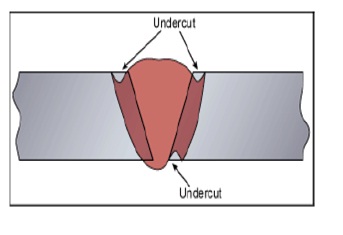

UNDER CUT –

“A defect that appears as a groove formed in the BM adjacent to the toe of a weld along the edge of the weld & left unfilled by the weld metal”.

Leave a Comment