Low Consolidation Testing:

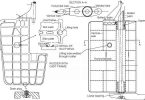

Flow properties tests are performed using a nike style shear testing machine. These tests the bulk strength and internal friction angles as functions of major consolidation stress for the bulk material, which allows calculation of storage facility design parameters. The consolidation stresses acting in a correctly designed hopper under flow conditions are relatively low. MAasurements of material properties at low consolidation pressures, including determination of compressibility (bulk density as a function of major consolidation pressures) and wall friction, allows calculation of design parameters to define the basic geometry of mass flow hoppers. Variable hopper geometry design charts will provide the necessary information to relate hopper half angles with critical arching dimensions and anticipated flow rates for both a conical and plane flow hopper design.