CARGO-HANDLING PREPARATIONS

In order to perform safe and complete cargo handling and transportation of vehicles, it is essential that adequate cargo-handling preparations be made for the following items.

Hold preparation (job under the ship’s charge)

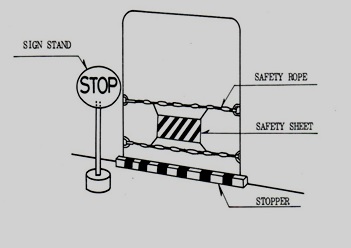

Dust and rust chips that can damage vehicles in the hold, should be removed, safety signs should be erected and other safety precautions taken.

Hold Cleaning

The inside of the hold should be thoroughly cleaned of moisture, salt, dust, rust chips and cargo particles left from the previous voyage.

Accumulation of rust on car deck

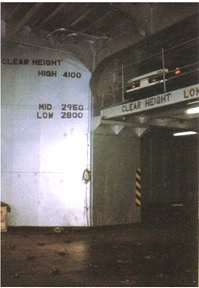

Maintenance of hold interior

Maintenance should be performed so that rust and salt water is prevented from falling onto the vehicles. The hatch covers should be checked fro water-tightness.

Rust on the under side of the car deck

Leave a Comment