Following hazards associated with DRI-

- Temporary increase in temperature of about 30°C due to self-heating may be expected after material handling in bulk.

- The material may slowly evolve hydrogen after contact with water (notably saline water).

- This cargo reacts with air and with fresh water or seawater to produce heat and hydrogen.

- Hydrogen is a flammable gas that can form an explosive mixture when mixed with air in concentration above 4% by volume.

- The reactivity of this cargo depends upon the origin of the ore, the process and temperature of reduction, and the subsequent ageing procedures.

- It is liable to cause oxygen depletion in cargo spaces.

- This cargo is non-combustible or has a low fire-risk.

- Oxygen in cargo spaces and in enclosed adjacent spaces may be depleted. Flammable gas may also build up in these spaces. All precautions shall be taken when entering cargo and enclosed adjacent spaces.

You may also know –

Direct reduced iron (DRI) is a highly porous, black/grey metallic material formed by the reduction (removal of oxygen) of iron oxide at temperatures below the fusion point of iron.

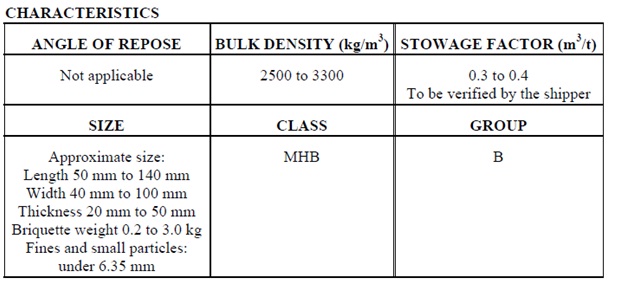

Cold-moulded briquettes are defined as those which have been moulded at a temperature less than 650°C or which have a density of less than 5,000 kg/m3.Fines and small particles under 6.35 mm in size shall not exceed 5% by weight.

Leave a Comment