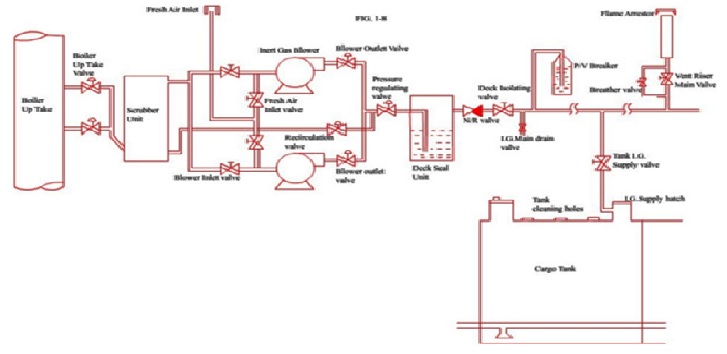

General arrangement of the inert gas system.

The general arrangement of the inert gas system is as follows:

- The inert gas generator-

Exhaust gas from the main boiler or the auxiliary boiler is used.

- Scrubber

This is installed to clean and cool the exhaust gas.

Working of scrubber:

The exhaust gas coming out of the boiler enter the scrubber and passes through a water seal in a water tank at the bottom of the unit. The gas then moves upwards and sea water is introduced at the top of the tower for cooling and purification. The sea water is then distributed into the space by means of a sprinkler system.

The water seal at the start is to prevent the inert gas coming out of the cargo tank from entering into the boiler.Its sought of another non return device. Its other function is to cool the high temperature exhaust gas.

Leave a Comment