The rudder is used to steer the ship. The turning action is largely dependent on the area of the rudder. The required area of the rudder varies with different type of vessels since desired maneuvering ability differs considerably and the general ship design may imposed restriction.

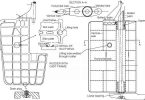

A rudder allows the ship to turn, simple plates have been superseded by plates welded to cast or fabricated frame.

Rudders are hollow and so provide for some buoyancy . In order to minimise the risk of corrosion internal surfaces are provided with a protective coating and some are even filled with foam.

A drain plug is provided to allow for the drainage of water , enable internal inspection to be made using fiber optic device and even allow for the limited application of a protective coating. Plates are welded to the frames internally in order to provide flush fitting , the final closing plate must be welded externally. A means of lifting is provided taking the form of a tube as close to the center of gravity as possible. Rudders are tested to a pressure head 2.4m above the top of the rudder.

In practice the rudder area is usually relative to the area of the immersed metal plane.

The ratio of the depth to width of a rudder is known as the aspect ratio and its value is generally 2. High aspect ratio is used in large vessels, where depth is not a constraint. Higher aspect ratio reduces the astern torque considerably.