In order to reduce or eliminate the adverse heeling effect of grain shift, the following methods may he used:

- a) Shifting Board (F+P)

- b) Over stowing (F+P)

- c) Strapping and Lashing (F+P)

- d) Bundling (F)

- e) Saucering (F)

- f) Feeders (F)

here – (F-filled,P-partly filled)

Shifting Board

- Longitudinal divisions (called shifting board), which must be grain tight may be fitted in both “filled” and “partly filled compartments”.

- In “filled compartments, they must extend downwards from the underside of the deck or hatchcovers, to a distance below the deckline of at least one-eighth the breadth of the compartment, or at least 0.6m below the surface of the grain after it has been assumed to shift through an angle of 15o

- In a “partly filled compartment’, the division, should extend both above and below the level of grain, to a distance of one-eighth the breadth of the compartment.

Over stowing

- For a partly filled compartments –topped off by loading bagged grain or other suitable cargo

- Surface to level off over and spread with separation cloth (gunny sack) or wooden boards

- Overstowed with sound well filled bags to a height of 1/16th the maximum breadth of the free grain surface, or to a height of 1.2 m whichever is greater

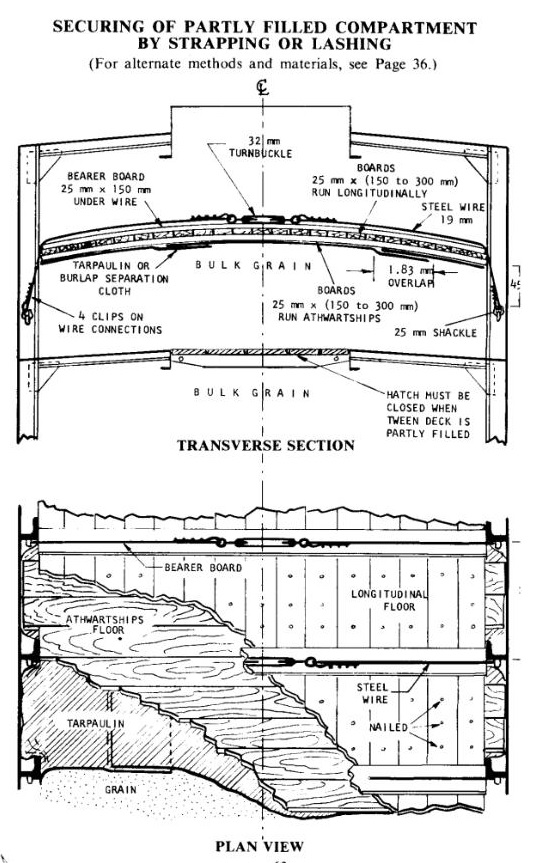

Strapping or lashing

- Surface of grain should be levelled but slightly crowned.

- Surface covered with separation cloths or tarpaulins, whose joints overlaps at least 1.83m

- Two solid floors of 25mm x 150mm to 300mm lumber to be laid athwartship-first tier and F&A-2nd tier.

- Lashed with double steel strapping, wires with ends at a point approx 450mm below the final grain surface.

- Lashings should not be placed more than 2.4m apart.

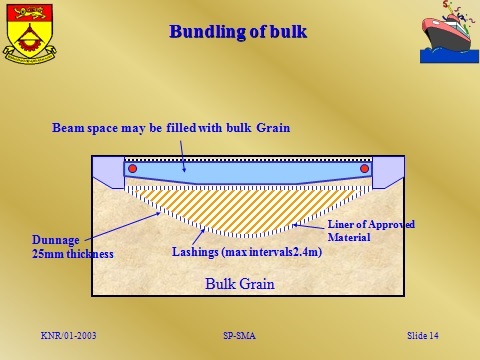

Bundling of bulk

- filled compartment”, shifting prevented by bundling the grain cargo.

- A bundle of similar bulk cargo is made by lining a saucer with tarpaulin or similar materials with suitable means of securing.

- Athwartship lashings to be placed inside the saucer formed in the bulk grain at interval not more than 2.4metres.

- Dunnage of not less than 24mm x 150 to 300mm to be placed fore and aft over these lashings to prevent the cutting or chafing of the material which is placed thereon to line the saucer. The saucer is filled with bulk grain and secured at the top.

- Further dunnage to be laid on top after lapping the material before the saucer is secured by setting up the lashings. If more than one sheet of tarpaulin is used to line the saucer, they shall be joined at the bottom either by sewing or double lap.

- The top of the saucer should be made level with the bottom of the beams when these are in place and suitable general cargo or bulk grain may be placed between the beams on top of the saucer.

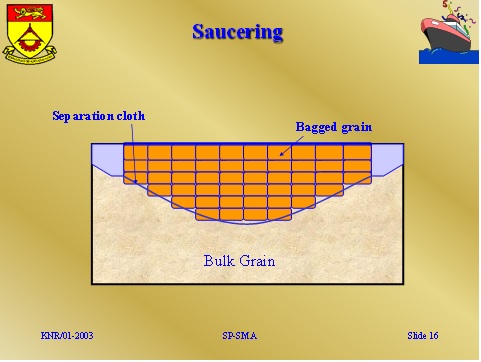

Saucering

- For filled compartment

- The top (mouth) of the saucer is formed by the underdeck structure in the way of the hatchway, ie, hatch side girders or coaming

- The saucer and hatchway above is completely filled with bagged grain or other suitable cargo laid down on the separation cloth and stowed tightly against adjacent structures and the hatch beams.

Feeders

- It may be assumed that under the influence of ship motion underdeck voids will be substantially filled by the flow of grain from a pair of longitudinal feeders provided that:

- The feeders extends for the full length of the deck and that the perforations therein are adequately spaced.

- The volume of each feeder is equal to the volume of the underdeck void outboard of the hatchside girder and its continuation.

Leave a Comment