- Inspect the piston, rings, and cylinder Wall.

- Wipe the running surfaces clean with a rag to ensure correct assessment of the piston ring condition.

- Use a powerful lamp to obtain a true impression of the details.

- Keep the records to form a “log book’ of the cylinder condition.

- Measure the total clearance between the piston rings and the ring grooves,

- Continue the inspection at the next cylinder whose piston is nearest BDC, and so on according to the firing order. Note down the order of inspection for use at later inspections.

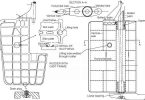

- Check the non-return valves (flap valves/ butterfly valves) in the auxiliary blower system for easy movement and possible damage.

- Remove any oil sludge and carbon deposits in the scavenge air boxes and receiver. Record the observations.