Co2 is only released when fire is out of control.

Action before releasing of co2

- Seal engine room.

- All ventilation to be closed.

- fuels and boiler within engine room to be shut down.

- Evacuate and seal the engine room. Head count.

- Check out the amount of CO2 required to be injected as per the planned injection information (found in CO2 room and remote station).

- Open fire cabinet door causing alarm to activate.

- Operate fire handle mechanism to fire the pilot bottles, which fires the bank of bottles in the engine room. Ensure hold valves are closed.

Operational procedure for releasing co2

- Evacuate all personnel

- Batten down and seal ventilation

- Stop all fans, fuel supply and boilers

- Sound audible and visual alarm

Limitation Of Co2 System

- Once used no replenishment at sea

- Isolation necessary (asphyxiation)

- No inspection to observe results

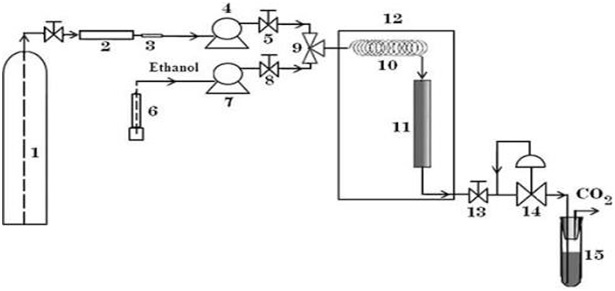

Planned Injection Information CO2

- CO2 arrangement plan.

- Procedure of firing.

- Number of bottles designated for each place protected.

- Number of non return valves.

Action After Releasing CO2

- Always advisable to wait before carrying out an investigation.

- Maintain boundary cooling and observe temperature at various levels.

- Once a distinct fall in temperature has been observed an internal inspection and assessment may be carried out.

- Breathing apparatus to be donned when entering the space. Checks on breathing apparatus, 2/E and oiler to enter.

- Inspection to be carried out with spray fire fighting equipment, safety line and communication checked prior to entry.

- Once it has been confirmed that fire has been brought under control an additional assessment by chief engineer.

- When both opinions agreed upon damage control party to be sent in for cooling down work. Learn CO2 arrangement system diagram, has been asked before.

CO2 Three Way Valve:

- Samples of smoke pass through a three way valve to the smoke detector system.

- This valve is shut but sample passes into the smoke detector.

- Once it is confirmed that there is fire open the valve.

- Smothering gas or CO2 can be injected into the hold via the valve.

Emergency Stop Valve

- This is usually of quick closing type. It fitted between the settling tank and the cold filters.

- This valve has an extended spindle or of remote control type to the deck to enable the oil to be shut off in the case of a fire out break.