- Make an enclosed space permit

- Stop engine and allow to cool

- Block the starting mechanism

- Shut off starting air supply

- Engage the turning gear

- Open indicator cock ( because air will compress and give wrong reading on turning the engine)

- Stop lubrication oil pump

- Put tag “ Men at work”

- Open crankcase and allow ventilation before entry

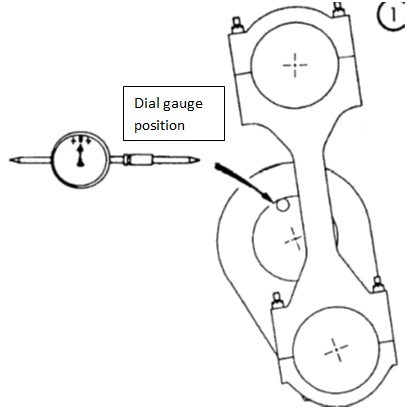

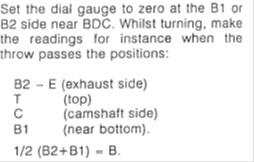

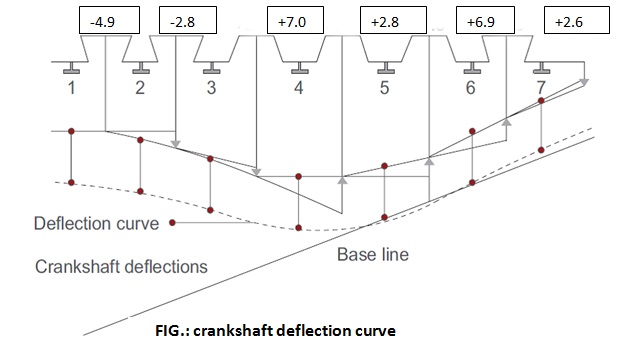

- Closing of the crank throw (compression of the gauge) is regarded as negative and opening of the crank throw is regarded as positive.

-

- The procedure is repeated for each unit and measurements are recorded.

Reasons of misalignment:

- Damage or wipe-out of the main bearing

- Loose engine foundation bolt leading to vibration

- Deformation of ship’s hull

- Crack in the bearing saddle

- Loose main bearing bolt leading to damage of main bearing

- Very high bending moment on the crankshaft due to excessive force from piston assembly

- Grounding of the ship Crankcase explosion or fire

- A defective or worn out stern tube or intermediate shaft bearings

- Loose or broken chokes in the foundation

- Bearing pockets cracked Bedplate deformed – transverse girder damaged

- Tie bolts slack or broken

- Weakening of structure due to corrosion

Why fore end and most aft end unit’s (main bearing ) deflection result are quite differ from others?