Points to pounder –

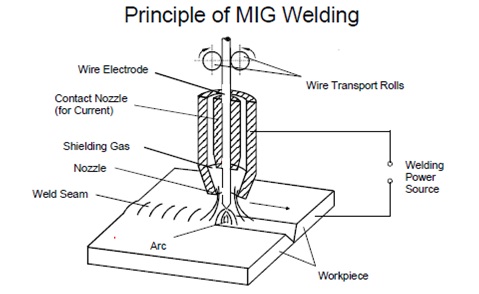

MIG (Metal Inert Gas) welding, also known as MAG (Metal Active Gas) and in the USA as GMAW (Gas Metal Arc Welding), is a welding process that is now widely used for welding a variety of materials, ferrous and non ferrous.

The essential feature of the process is the small diameter electrode wire, which is fed continuously into the arc from a coil. As a result this process can produce quick and neat welds over a wide range of joints.

Equipments required for MIG welding –

- DC output power source

- Wire feed unit

- Torch

- Work return welding lead

- Shielding gas supply, (normally from cylinder)

MIG welding is carried out on DC electrode (welding wire) positive polarity (DCEP). However DCEN is used (for higher burn off rate) with certain self shielding and gas shield cored wires.

DC output power sources are of a transformer-rectifier design, with a flat characteristic (constant voltage power source). The most common type of power source used for this process is the switched primary transformer rectifier with constant voltage characteristics from both 3-phase 415V and 1- phase 240V input supplies.

Leave a Comment