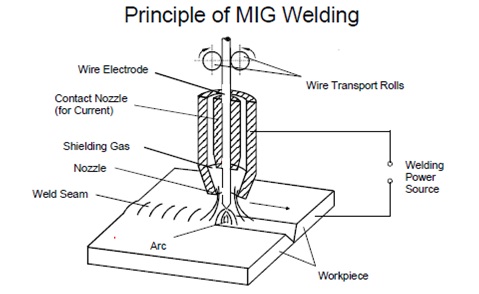

An electrical arc is created between a continuous, consumable wire electrode and the work piece. The consumable wire is fed through a gun, functioning as the energy source as well as filler material, in turn, establishing a continuous weld (or puddle). Once contact is made between the clamped piece and the wire electrode, the circuit is completed.

MIG welding is conducted using inert gases.

The arc is drawn between the melting wire electrode and the work.

The current to the positively poled wire is supplied through a contact nozzle (tip). Here it is possible to work with high current densities (> 100 A/mm2).

The melting power of MIG welding is thus very much higher than with the TIG process. Contact nozzle and the relatively short wire end are surrounded by inert gas.

This gas serves to protect the melt pool, wire and arc as well as to cool the contact nozzle.

In comparison, the current densities used for TIG welding with alternating current lie around 20 to 30 A/mm2.

Leave a Comment