Valve seat and valve spindle are grind at different angle so that we can get the perfect sealing.

Clearances to be checked:

- Checking the exhaust valve spindle bushing

Check the surface clearances and inspect the bushing for wear.

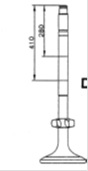

- Checking the spindle stem for wear

Check the spindle stem for wear. If the stem diameter is less than stated in data or manual or the chromium layer is worn out, send the spindle for reconditioning at authorised workshop.

- Checking the bottom seat surface

Checking with the help of template, you can check whether clearances are in the right limit or not. Before putting the template, it is wise to remove any type of carbon being deposited on the seat.

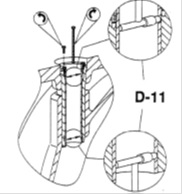

Outer seating needs to be lapped smoothly, with the help of special tool shown below. The lapping needs to be one half turn clockwise and half turn anticlockwise.