DNV GL has observed an increasing trend in reported incidents involving aft propeller shaft bearing damages. Most of the damages reportedly have developed within a short period of time, typically a few minutes to an hour, under the respective operating conditions.

This technical news reflects what is suspected to be one of the contributory factors to some of these types of damages, namely operation involving incomplete propeller immersion. It is recommended that operators undertake suitable precautions and respective mitigating measures in this regard.

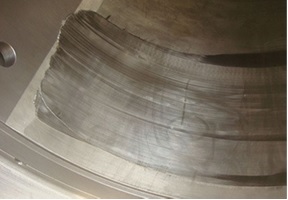

Typical damages observed and their consequences

Figure 2: Typical damages observed in this regard involve wiping of white-metal based bearing material in the aft part of the bearing, indicating a complete or partial loss of the hydrodynamic oil film under the reported operating conditions.

Physical contact of the shaft with the bearing material is reflected by an elevated bearing temperature and, in most cases, at an exponential rate of rise.

In an isolated case involving extended operation beyond the alarm point (normally 65°C), bearing damage was even observed with a slower rate of temperature rise.

The reported damages resulted in expensive and time-consuming repairs. Bearing failure may lead to the risk of total loss or diminishment of main propulsion function capacity and, in some cases, may be detrimental to the propeller shaft in the event of steel-to-steel contact.

In the event of long-term operation with incomplete propeller immersion which does not result in an immediate failure, the risk of fatigue-related bearing failures arising out of excessive cyclic loading and associated shear forces on the bearing will co-exist.

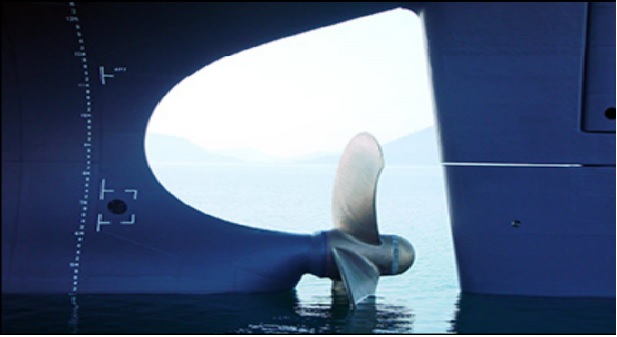

Typical design consideration – complete propeller immersion

Design criteria regulated by applicable DNV GL rules cover complete propeller immersion. Design margins also cater for some eccentric propeller loading, for instance, due to an inhomogeneous wake field and/or operation with the propeller blade tips in close vicinity of the water surface.

The shaft alignment philosophy incorporates an acceptable distribution of loading on the shaft bearings while taking into consideration the forces and associated bending moments induced by the propeller during operation. The propeller weight and hydrodynamic forces influences the angular misalignment of the shaft in way of the aft bearing (relative slope) and, subsequently, the shaft-bearing contact area.

Hydrodynamic lubrication conditions are predominantly influenced by the RPM, diameter of the shaft, viscosity of the oil, the net effective contact area of the shaft in way of the bearing and the bearing load. Contact area also regulates the local surface pressure applied on the bearing.

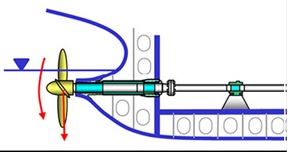

Exceptional operating condition – incomplete propeller immersion

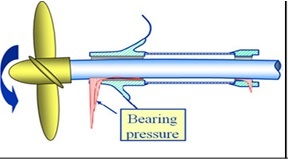

Figure 3: Typical downward bending moment induced by propeller (incomplete propeller immersion)

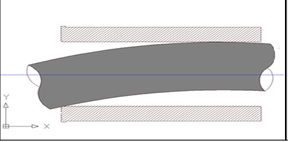

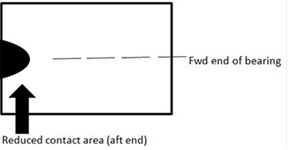

Figure 4: Increased relative slope in way of the aft bearing (edge contact)

Figure 5: Contact pattern in way of the aft bearing

Figure 6: Exponential increase in local surface pressure

Operation with incomplete propeller immersion may induce an excessive eccentric thrust on the propeller and, consequently, a downward bending moment on the shaft. This may result in exaggerated localized loads (edge loading) and surface pressure on the aft bearing arising out of an increased relative slope and reduced bearing contact area (Figures 3, 4, 5, 6).

Localized bearing loads acting on a diminished contact area, not catered for in the design criteria, lead to total or partial loss of an effective hydrodynamic oil film of minimum thickness. Hence, the risk of prospective consequential bearing damage co-exists under exceptional operating conditions with incomplete propeller immersion.

The additional bending moment generated is a function of the degree of lack of propeller immersion, RPM and the power. Elaborating this further, the bending moment is proportional to the thrust force, which is proportional to the square of the RPM. Consequently, increasing RPM introduces an exponential degree of risk in a partially submerged propeller condition.

Recommendations to Operators

Operators are recommended to undertake suitable precautions during operation to ensure complete propeller immersion.

This may typically be achieved by a combination of:

- Suitable means of information in the on-board operating procedures

- Promoting increased awareness of the risk involved

- Defining precautionary measures under exceptional conditions

If exceptional operating conditions are unavoidable, e.g. reduced sea depth, light conditions to enter a dry dock or ballast exchange at sea etc., it would be prudent to carry out satisfactory design/risk assessment and the respective mitigating measures.

Such measures may include:

- Lower RPM/power

- Limited steering angles

- The use of tugs

Other risks arising out of similar operating conditions, e.g. change in torsional vibration characteristics, also need to be managed, but are not included in this technical news