Precautionary Measures

To minimize the risk of being exposed to this fraudulent practice, the following points should be considered:

- The Chief Engineer should board the barge prior to and on completion of bunkering to check the tank quantities together with the Barge Master. All tanks should be sounded including slop tanks and any compartments that may contain fuel intended for other vessels. The sounding records should be signed by both the Chief Engineer and the Barge Master.

- The temperature of the fuel oil should be measured before the transfer takes place so that the fuel oil density can be calculated accurately.

- The draughts of the bunker barge should be taken prior to commencing bunkering and on completion together with the Barge Master in order to compare the change in displacement with the quantity of fuel oil delivered.

- If all the product on board the bunker barge is to be transferred to the vessel, any attempt to introduce air into the fuel oil is likely to have taken place already as doing so during bunkering will make it appear that the vessel has been over-supplied.

- Vessels making brief bunker calls or which are supplied shortly before departure may be more at risk than others given that Masters may be under pressure to sail on completion and may be less inclined to become embroiled in a bunker dispute.

- If it is thought that compressed air may be present in the fuel oil, no reliance should be placed in volumetric or positive displacement flow meters (ie the equipment most commonly found on vessels) as they may be fooled into producing artificially high readings. Mass flow rate meters, such as versions of the Coriolis meter, will produce more accurate readings, but such devices are not generally fitted to vessels at present.

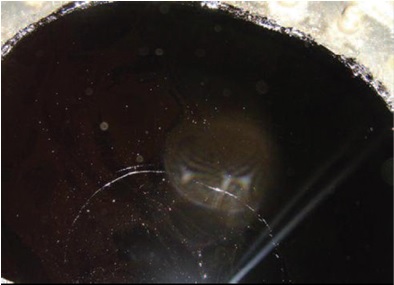

How the surface of the fuel oil should look – no cappuccino effect evident

I never learn this in maritime school. Thanks MG for uptodate articles on latest ideas and knowledge. While taking ullage, i’ll refer this to my pumpi..