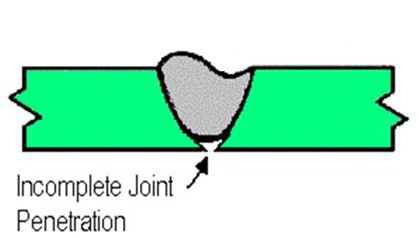

- Acts as stress riser from which a crack may propagate

Cause –

- Root gap too small

- high welding speed

- Low heat input

- Too large electrode dia

Prevention:

- Proper joint preparation

- Proper heat input & welding speed

- Use suitable size of electrode

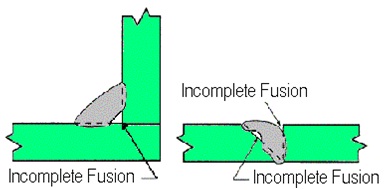

LACK OF FUSION

“Lack of complete melting/ fusion of some portion of the weld metal in a joint”

- May be at the root, sides or between two runs.

- Reduces the strength of welds & makes welded structures unreliable.

Cause:

- Low welding current

- Excess welding speed

- Unfavourable heat input

Prevention:

- Maintain proper current & welding speed

- Proper cleaning of each bead.

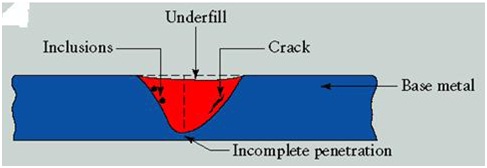

Slag inclusion-

Metallic or nonmetallic solid material entrapped within the WM, between weld passes or between WM & BM”.

Leave a Comment