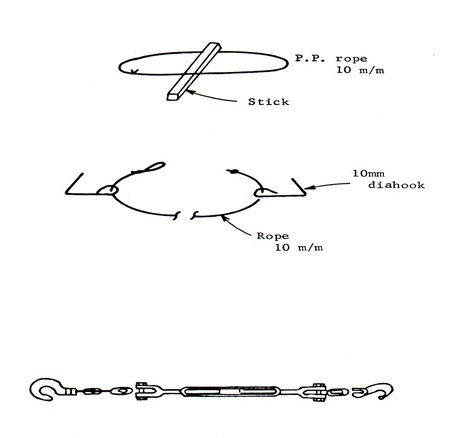

- Hand rope tightening method (often used on north European ships)

Shearing strength: 2,200kg

- Chain and turnbuckle method

Load capacity: 1—5 tons

Shearing strength: 4—20 tons

Though the method varies according to different conditions, lashing methods for vehicles of under 1 ton in weight are as outlined below.

- Fore and aft stowing

Front: 2 points

Rear: 2 points

Total 4 points

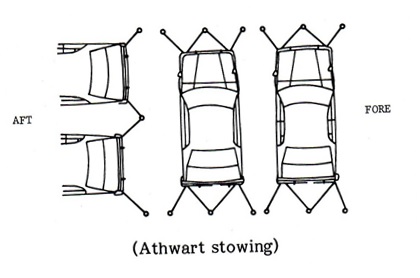

- Athwart stowing

Front: 3—4 points

Rear: 3—4 points

Total 6—8 points

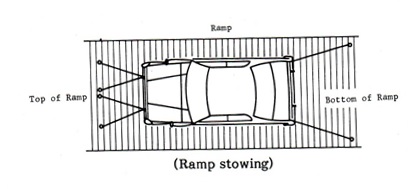

- Ramp stowing

Top: 3—4 points

Underside: 2 points

Installation of wheel blocks

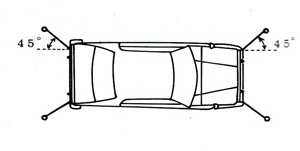

- The desirable lashing angle is 45o and the belt should not twist.

Lashing should be adequately tight with 4—8 points of lashing evenly fastened.(with adequately tightened lashing belts, the vehicle is normally pressed down by 20—30 mm.)

While cross lashing should be avoided as much as possible, if it is unavoidable because of lashing points, it should be adopted by making sure that lashing materials are not in contact with each other.

After completing lashing, the tension of the rope or belt should be checked by stepping on it.

One member of each gang should be assigned to inspect whether lashing has been forgotten, whether lashing has been inadequately tightened, whether positions are suitable, etc.

Workers should not put their hands on the vehicle, lean against it, sit or stand on the bumper, etc. (prevention of dents and scratches)

When transporting materials, make sure that they do not touch vehicles.

Headlights should not be used for lashing work.

Tools covered with rudder, etc., should be used for lashing work so that vehicles will not be damaged.

Leave a Comment