-

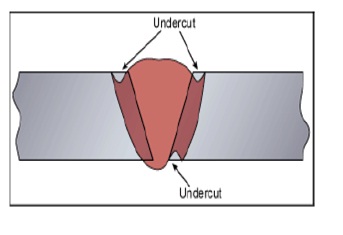

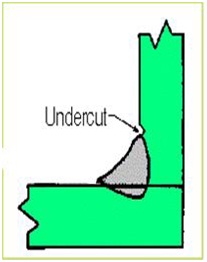

UNDER CUT –

“A defect that appears as a groove formed in the BM adjacent to the toe of a weld along the edge of the weld & left unfilled by the weld metal”.

- Generally located parallel to the junction of weld metal & base metal at the toe or root of the weld

- Reduces the cross-sectional thickness of the base metal

- Acts as stress raiser in fatigue loading

Cause and prevention of undercut:

Cause –

- High welding current & arc voltage

- Too large electrode dia

- Incorrect electrode angle

- Longer arc length

Prevention:

- Use prescribed welding current for electrode size.

- Adjust electrode angle to fill undercut area.

- Correct travel speed, arc length, etc.

Leave a Comment