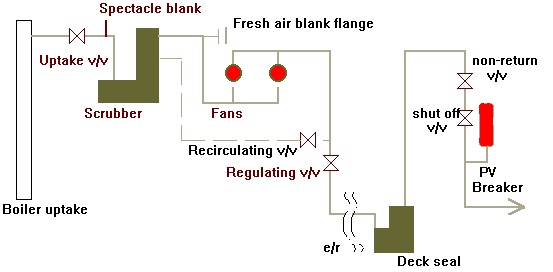

Followings are component of IG plant;

Boiler uptake valve- Provides a take off point for the flue gas, A cleaning arrangement is fitted to prevent soot build up.

Scrubber- Flue gas passes to the scrubber via the uptake valve, here it enters at the bottom via a waterseal and passes up through a series of sea water sprays and baffle plates being cooled and cleaned before exiting via a demister

The water is supplied via the scrubber pump, the sprays reduce the temperature to within 2oC of the sea water temperature, the sulphur dioxide content is reduced 90%, and the gas is clear of soot.

The tower is rubber lined and other parts are made of inconel or glassfibre to protect against the SO2 .The water seal at the bottom is provided by the weir arrangement fitted to the drain system.

The following alarms are fitted;

Leave a Comment