-

Slag inclusion-

Metallic or nonmetallic solid material entrapped within the WM, between weld passes or between WM & BM”.

- May be in the form of slag or any other foreign material, which does not get a chance to float on the surface of the solidifying WM

- H₂: the most undesirable inclusion (causing: cold crack)

- Lowers the strength of joint & make it weaker

- Non- metallic inclusion:-

–Most dangerous

–May be sulphide, oxide, silicate or aluminate type

–Acts as stress raiser

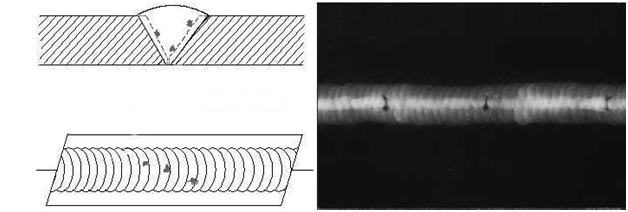

- Slag inclusions are elongated or globular pockets of metallic oxides and other solid compounds.

Causes for slag inclusion:

–Inadequate cleaning of weld metal between passes

–Rapid rate of welding

–Too large electrode

–improper current

–Long arcs

Prevention :

–Maintain proper current & heat input

–Proper cleaning of weld.

According to the American Society of Mechanical Engineers (ASME) welding defect causes are following :-