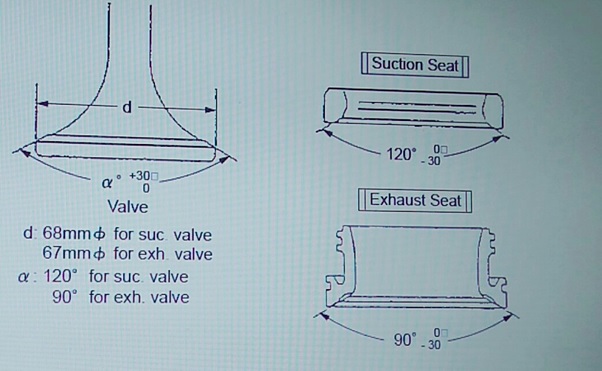

If there is a flaw in the valve seat of suction and exhaust valve, valve seat must be grinded appropriately as per engine maker’s instruction guide. Suction v/v seat should be grinded at 120° while exhaust v/v seat should be grinded at 90° as shown in the figure below .

FIG.: Angle of suction/ exhaust valve seat

Procedure for grinding of suction/ exhaust valve:

- Checking the clearance between the valve guide and stem, replace the part which has got wear down and then perform a valve grinding.

- Perform the individual valve grinding earlier than usual. Judging the situation, determine the interval of subsequent servicing.

- Apply the proper quantity of grinding compound to the valve to be ground, and elaborately grind the valve with the specified grinding tool.

- Finally grind the valve with the oil.

- If a flaw on the valve seat of a suction/ exhaust valve is so deep that it is required to be corrected by grinding, finish grinding the valve seat part in an angle shown in the figure below and the outer periphery of the valve seat part makes contact with the valve.

Proper tools must be used during grinding and should be carried out by experienced person.