Precautions and procedures before removing cylinder head:

- Inform company and take permission.

- Take immobilisation certificate from port state control.

- Read the manual and have a tool box meeting with everyone involved in the job. Discuss the complete procedure.

- Prepare important tools and spares required for overhauling liner as given in the manual

- Prepare risk assessment and make sure all personal safety equipment are used

- Close the shut-off valves on the starting air receivers. Close all the shut-off valves in the control air supply and safety air unit and open the drain cocks in the two air receivers.

- Close by hand the automatic starting air shut-off valve and open the vent and drain valve to the main starting air piping on the engine as well as the vent valves on the automatic starting air shut-off valve, and leave them in this position until maintenance work is completed.

- Open all indicator cocks on the cylinder covers and leave them in this position until maintenance work is completed.

- Engage turning gear (gear pinion must be in engaged position) and lock the lever

- Stop main lube oil pump and switch off the breaker. Put the tag ‘Man at Work’

- Once the engine jacket temperature comes down, shut the inlet water valve for the unit to be overhauled.

- Keep other units in Jacket preheating system to maintain the jacket temperature.

- Drain the jacket water of the concerned unit.

- Remove jacket water connection.

- Remove high pressure hydraulic pipe connection to the exhaust valve.

- Shut the fuel oil to the particular unit whose liner is to be removed.

- Dismount high pressure fuel pipes to the cylinder.

- Remove exhaust bellow.

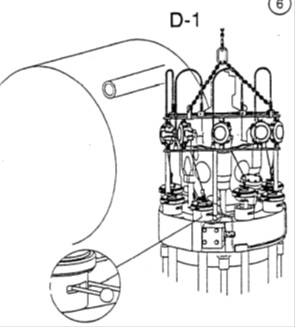

FIG.: Removal of cylinder head

Dear Sir,

pleasure to learn and have applied in my MEO CL 2 answer paper , and gained my achievement. Awaiting for your further this types of simple form of guidance regarding my / our further questions.

thanks with best regards ,