What is COPT?

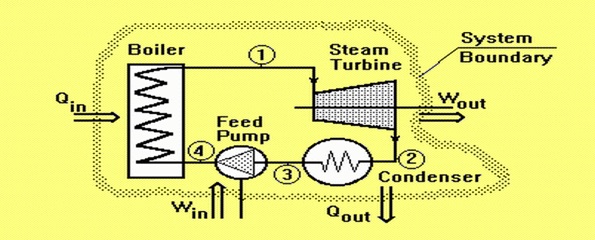

Cargo Oil Pump Turbine (COPT) System is found on the Oil Tankers. It has two systems working together to collectively discharge the oil. One system is the driving force which gets the power from steam to drive the second system, the centrifugal pump system. Steam section has a turbine, which produces a tremendous force and gives a higher rate of discharge. They can be vertical or horizontal in design.

Working of COPT

COP is driven by a steam turbine, which gets a high pressure steam of 16kg/cm2 from a boiler. Generally, oil tankers have two auxiliary Boilers of nearly 16kg/cm2 working pressure capacity. This steam gives a tremendous force to the impeller and impeller shaft which produces a high suction force. In result of this good discharging rate can be achieved, which will ultimately save money for the Ship’s Owner by reducing port charges. According to the size and other specifications, COP can run at a speed of 2800m3/h with a revolution of 1510 rpm.

Dear Sir

Thanks for your useful article.

nice??????

Good post brother. I am saving it for my tanker days.

Very good, easy to read, understand and grasp above mentioned points especially for the ones willing to join tankers for the first time. Expecting more from you brother. Keep it up.

Good effort. Keep writing.Reading n writing are the best companions. Congrats for ur first article.

Visitor Rating: 5 Stars

Visitor Rating: 5 Stars